Motor protector

Contact us

Fax:0577-59921167

Chief:Mr.chen

Address:Geyao Building, the Junction of Shanhai Road&Haixia Road, Industrial District, Cangnan County, Zhejiang Province

Zip:325800

E-mail:cngydz@163.com

Set design, development, production, production and sales services as one of the diversified enterprises, the original high-end motor protector, successful research and development of intelligent integrated motor protector, motor protector, microcomputer protector, power meters, switchgear intelligent control device, service robot and other products.

-

Product Details

GY102 Motor Protectiom Device

1, Summary

GY102 motor protection device is the result of the experience accumulation from the motor protector & the microcomputer protector research &production and the modern high-tech. It is a all-round motor protection device which is made by import integrated circuit,intellectual property right and software copyright, and has the advanced fieldbus interfaces. It protects and controls the motor by microprocessor and supports the feeder protection to complete the motor operation, autodiagnosis, communication with upper computer and so on. Its measure protection avoided the productive accidents caused by the motor fault like overload, locked-rotor, overvoltage, undervoltage, underload, open-phase, electrical grounding earth etc., and ensured the equipments ’ normal function and safety .

A perfect motor protection device is the comprehensive device which can collect, calculate, analyse, monitor, alarm and control all kinds of working motor’s information data. The device completes the timely and accurate protection to ensure the production safety through fault alarm, protection action (protection tripping) and action time delay. It can also do the real-time monitoring for the working motor’s slight informations on the upper computer through the data information communication and provide the management information through the computer data processing. The device will send out limit alarming before the equipment may cause serious fault so that the managerial staff can deal with the fault in time to avoid the unexpected stop making influence to the normal production and maximize the effectiveness of equipment operation and control. When the motor’s working parameters reach the set alarming value,the protection device just do the alarming but will not do the tripping.When the working parameters reach the set tripping value,the device will enter the tripping delay time.The tripping action will be cancelled if the equipment return to the normal function within the set tripping delay time.But the tripping action will be carried out if over the tripping delay time,the motor will be power off. Every kinds of protection information will update to the computor manage system through the communication interface while the device do every protection function.

2, Main features

Use the advanced microcomputer technology and high performance integrated chip.own powerful function and superior performance.High testing accuracy, good linearity, high resolution, strong anti-interference ability and reliable protection action.Three-phase current, phase voltage and various fault codes are displayed on LED or LCD intuitively and clearly. Good stability so that It can do the long term work without maintenance.

E2PROM storage technology is used to realize the parameter setting,the setting parameters can still be saved after power down,there is no need to reset.One device with multiple functions,Can replace the traditional products such as current transformer, ammeter, voltmeter, thermal relay, time relay, motor protector of breaking phase, leakage protector and so on.

A perfect microcomputer protection monitoring device is to sample and track the detailed information of the working motor,and complete the timely and accurate protection through the fault alarm, protecting action and action time delay to ensure the production safety.

3, Basic protection function

start-up protection: Only do the protection for the open-phase,overvoltage. Undervoltage,short-circuit and three phase unbalance,overtime start-up within the start-up time.

overvoltage protection: Will function within 6s when the working voltage is bigger than the set value(factory default value is 260V)

undervoltage protection: Will function within 6s when the working voltage is smaller than the set value (factory default value is 180V)

open-phase protection: when any phase is power off,function time≤2.0s

locked-rotor protection: when the working current reached the multiples of the set value, function time≤2.0s

unbalance protection: when any two phase's current difference reached the set percentage,function time≤2.0s

underload protection: When the working current is continuously smaller than the set underload limit,

function time≤2.0s.

leakage protection: When the zero sequance tansformer detected the leakage current reached the set value,

function time≤1.0s.(factory default value is 1)

Short-circuit protection: when the short-circuit current value reached 5 multiples of the set leakage current value, function time≤2.0s

Overload protection: overload protection function time is inverse-time protection or tripping protection,

function time(refer to chart 2)

(Chart 1)

Current specification

| Model | Current Spec(A) | Spec | Remark |

| 10A | 1-10A | 0.3-3KW |

wiring through protector A/B/C current transformer directly |

| 20A | 2-20A | 1-7.5KW | |

| 50A | 5-50A | 4-30KW | |

| 100A | 10-100A | 7.5-45KW | |

| 200A | 20-200A | 25-75KW | |

| 300/5A | 60-300A | 45-110KW | equipped with 300/5CT |

| 400/5A | 80-400A | 55-132KW | equipped with 400/5CT |

| 500/5A | 100-500A | 75-250KW | equipped with 500/5CT |

| 800/5A | 160-800A | 90-300KW | equipped with 800/5CT |

(Chart 2)

Inverse time-limited action:unit S

Power on auto-start: The protector owned this function is need to set the auto-start time, the motor can not be

communication started without setting. (factory default is ‘0’ stop function)

Start timeout protection: will be judged as start timeout if the actual current is still bigger than the overload

current when the start time delay is over。(factory default is 4s,1-120s settable)

Contact point capacity:AC220/5A AC380V/3A lifetime≥105times。

Contact point features:Contact point J1 normal close,Contact point J2 normal open。(Based on the shell

wiring diagram)

Tolerance:±5%

Split display:distance <500cm standard configuration 100cm

Set function:The protection parameters are set according to the current value of the nomal working motor

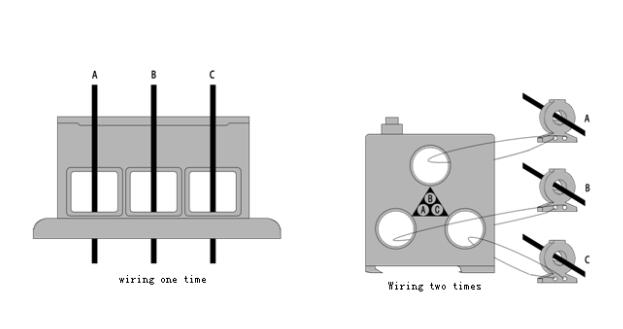

Matching function:Protectors under 200A and 200A do not need to be configured with transformers, and protectors larger than 200A need to be equipped with three standard transformers with a conversion ratio of 5A. For example, 400A specifications require current transformers with 400A/5A.

Protocol:Support the manufacturer programming MODBUS and other communication protocols.(note when is ordering)

Current Output:The average value of three-phase current is converted to DC4-20mA signal output.

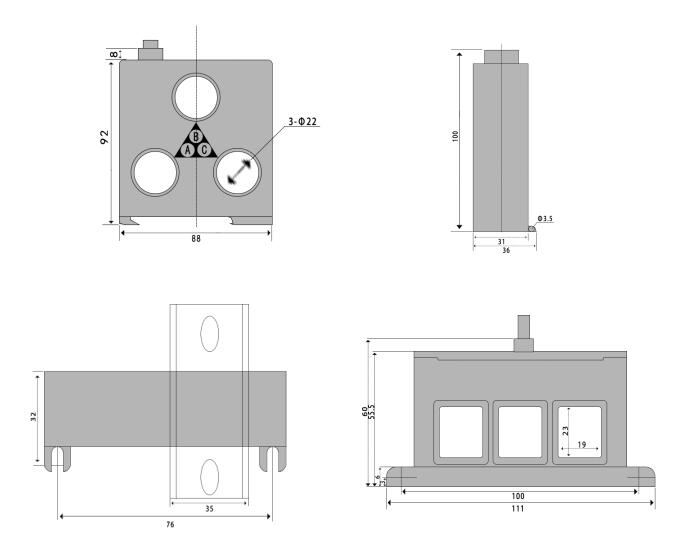

Remark:1、It’s better to fix the transformer under the AC contactor ignoring the transformer direction, and installed by screw fixation and standard 35mm lead-rail. The three-phase main circuit passes through the three holes of the transformer. Power on only After the shell wiring diagram is connected to the secondary line and checked correctly.

2、The protector’s AC power supply should be connected in front of the AC contactor to ensure the protector long-term power supply.

During the operation, the current value of the A, B, C phase is displayed in the loop, and each phase is displayed for 3 s. When the motor is overloaded, the overload indicator light starts to winking. The larger the overload current, the faster the overload light winks. The wink will disappear after tripped or the current returns to normal.

When the fault reaches the action time, the tripping signal is issued, the corresponding fault indicator lights up, and the fault code is displayed. The motor can be started automatically or manually by pressing the reset button to clear the fault if there is no self-start function. With self-start function, the device must be powered off for 30s before rebooting.

After shutdown, press shift button to query the fault record (1 for the latest fault), press the data key to query the working time and accumulative running time of the motor each time.

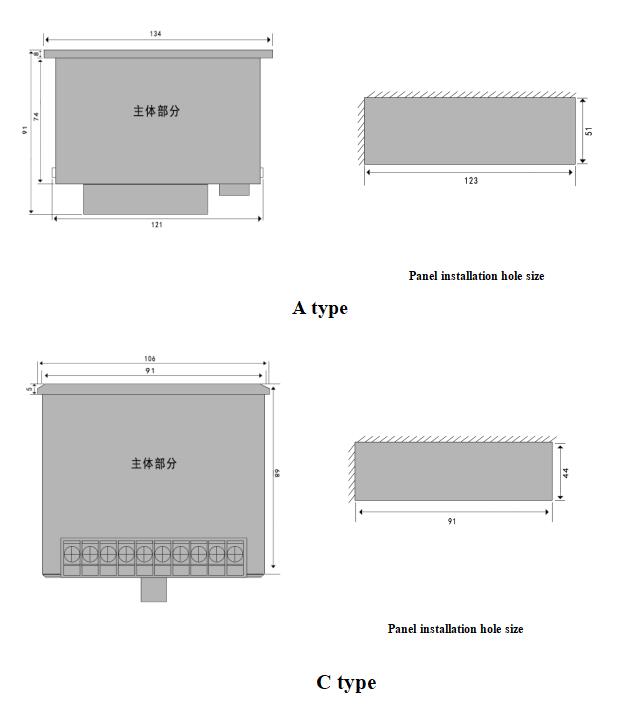

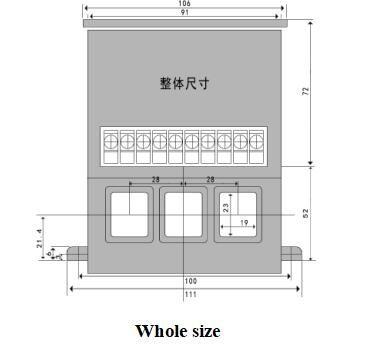

5,Installation size

Device size:134x63x91mm or 106x58x68mm hole size:121x50mm or 91x44mm

Device size:106x58x124mm

Spilit current transformer(round shape or square shape selectable,wiring from both sides)

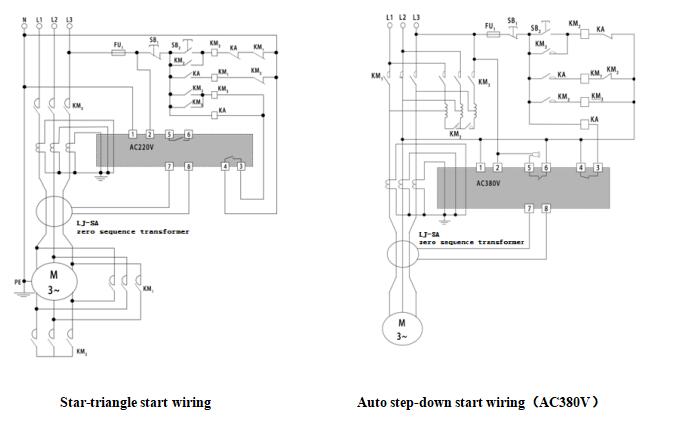

6,Typical wiring

7,Wiring terminals instruction(refer to the product cover wiring diagram )

1) J1 protection normal close point;J2 Signal output normal open point.

2) Wiring with upper computor to connect the TA,TB With fieldbus.

3) Will supplement if customers have different requirement for the secondary wiring method

4) The zero sequence transformer signal line is connected to the protector’s 7,8 terminal with leakage function.